Desiccant dehumidification systems are required, when the desired dry air dew point is less then + 10 °C. This is below a mixing (or humidity) ratio of less than 7,5 g/kg

Applications

Dewpoint < +10 °C

desiccant dehumidification

application range: frost point -50 °C … dewpoint +10 °C

Dewpoint > +10 °C

condensing dehumidification

only for dewpoints > + 10 °C

Where is a dew point of < 10 °C needed ?

- production, storage and packing of hygroscopic materials

- steel corrosion inhibition

- condensation prevention

Production, Storage and Packing of Hygroscopic Materials

In this area the so-called equilibrium moisture of the product or material is important. The moisture content of every material is in equilibrium with the relative humidity of the ambient air. If the material is processed, stored or packed in air with high relative humidity it takes up moisture until its moisture content is again in equilibrium. This often has undesirable consequences: sugar in humid environment gets tacky. The equilibrium moisture is shown in sorption isotherm graphs:

Examples: relative Humidity φ in % RH / moisture content WG in %

wood, paper

sugar

some typical applications are:

- pharmaceutical industry – tableting, granulation, sugar coating, packing

- food industry – e.g. waffles will be especially crispy when cooling the cream filling in a cooler with dry air

- storage of predried wood, fertilizer, etc.

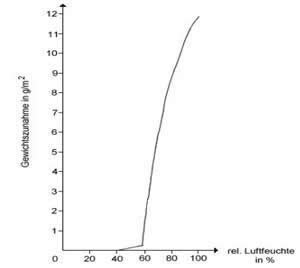

Corrosion Prevention

When storing steel at less then 50 % RH no corrosion is occurring:

see diagram

relative humidity in % / weigth increase in g/m²

typical applications are:

- coil storage

- shutdown preservation of turbines and boilers

- sandblasting and painting of ships and bridges

- value conservation of classic cars

Condensation Prevention

Reaching the dew point leads to condensation on cold surfaces, causing corrosion of pipes and structural damage to buildings.

Example:

In summer ambient air with 20 °C und 60 % rel. RH has a dew point of approx. 12 °C.

A pipe with surface temperature of 8 °C will be completely wet.

In hydroelectric power stations and water plants dry air is used to prevent condensation. Desiccant dehumidification is useful at water temperatures and thus surface temperatures below +10 ° C. Special humidity sensors allow controlling the humidity exactly at surface conditions.

Questions?

The decision if a desiccant type dehumidification system is needed is therefore depending on the product or material properties. To achieve the desired dehumidification result depends not only on providing dry air but also very much on proper air ductwork and distribution design.

For all your questions SORPTION.CC is available as the Competence Center for Desiccant Dehumidification.